Driving Innovative Solutions from Indoor to Fenceline

Cerex proudly partners with Sonoma Technologies (STI) to implement comprehensive monitoring solutions across the United States. Combining Cerex’s real-time software with STI’s web-based solutions gives our clients unmatched flexibility for storing, monitoring, and presenting useful data.

Featured Projects

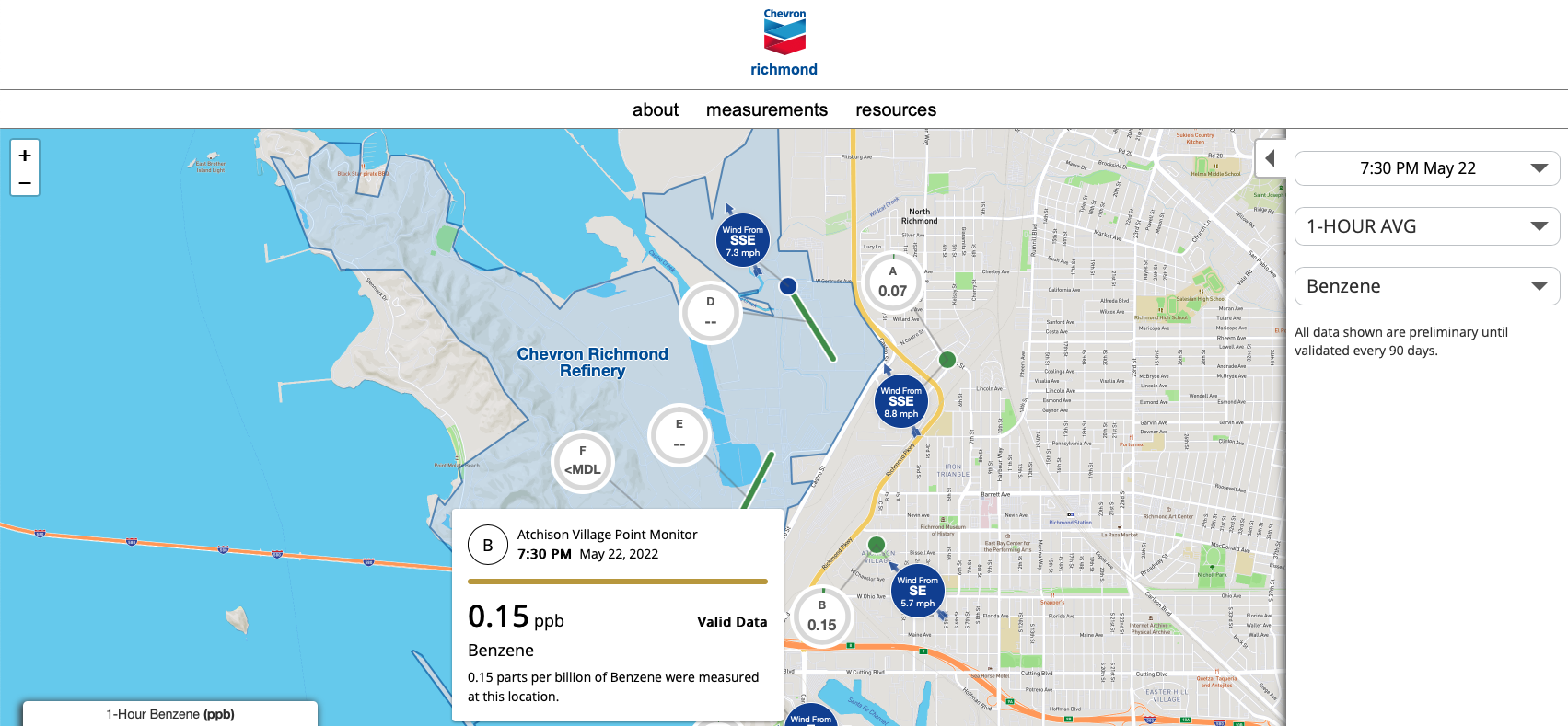

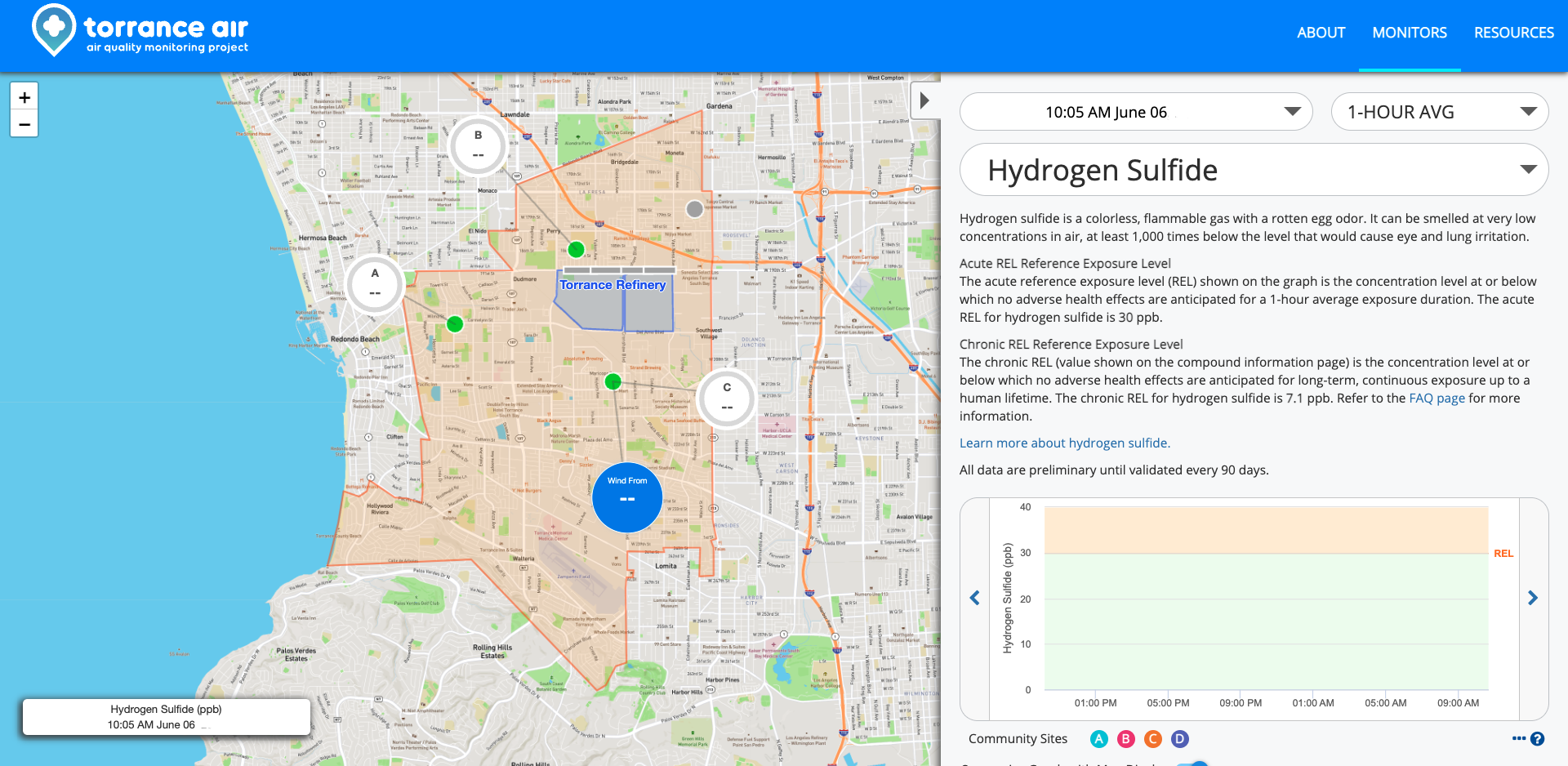

Below are a few examples of our current installations in North America for some of the world’s largest petrochemical companies, as well as federal agencies such as the U.S. Army Corps of Engineers. These examples below display our equipments’ monitoring activity in real-time measurement data on our partner websites.

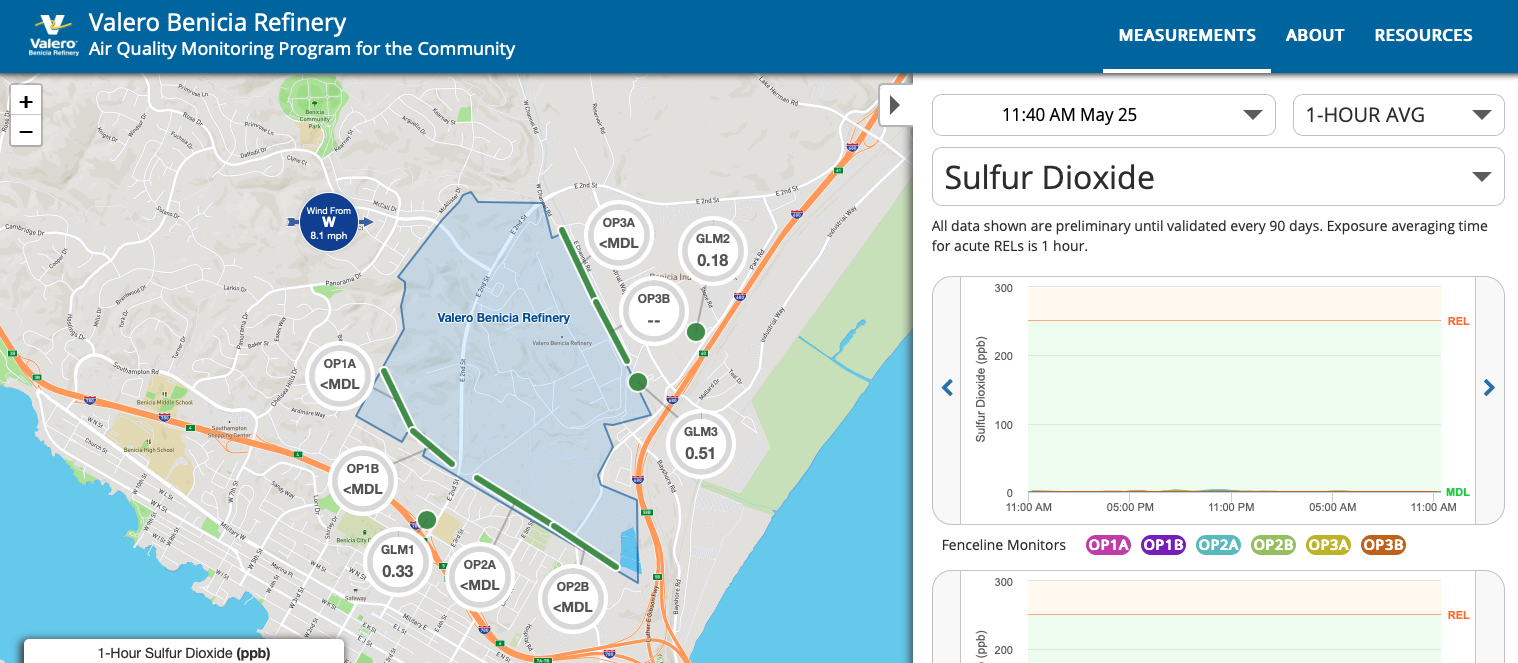

Like other refineries in California, Valero first contacted Cerex in 2017 in response to BAAQMD Rule 12-15. In compliance with the new regulation, the Benicia refinery acquired 4 Cerex UV Sentrys, and tunable diode lasers (TDLs), to satisfy the BAAQMD stipulation that states “open-path technology capable of measuring in the parts-per-billion range regardless of path length”. Today, these analyzers help the Benicia refinery measure benzene, toluene, ethylbenzene, xylenes (BTEX), and Sulfur Dioxide. Cerex-provided TDLs measure Hydrogen sulfide (H2S).

These monostatic, UV-DOAS, open-path analyzers with xenon sources help cover emissions for Benicia operations that span roughly 330 acres. As with all other installations, measurements are made available in real-time. In partnership with Sonoma Technologies, a public-facing website was constructed with real-time data from Cerex’s analyzers and is updated every 15 minutes for community transparency.

Products Used in this Solution

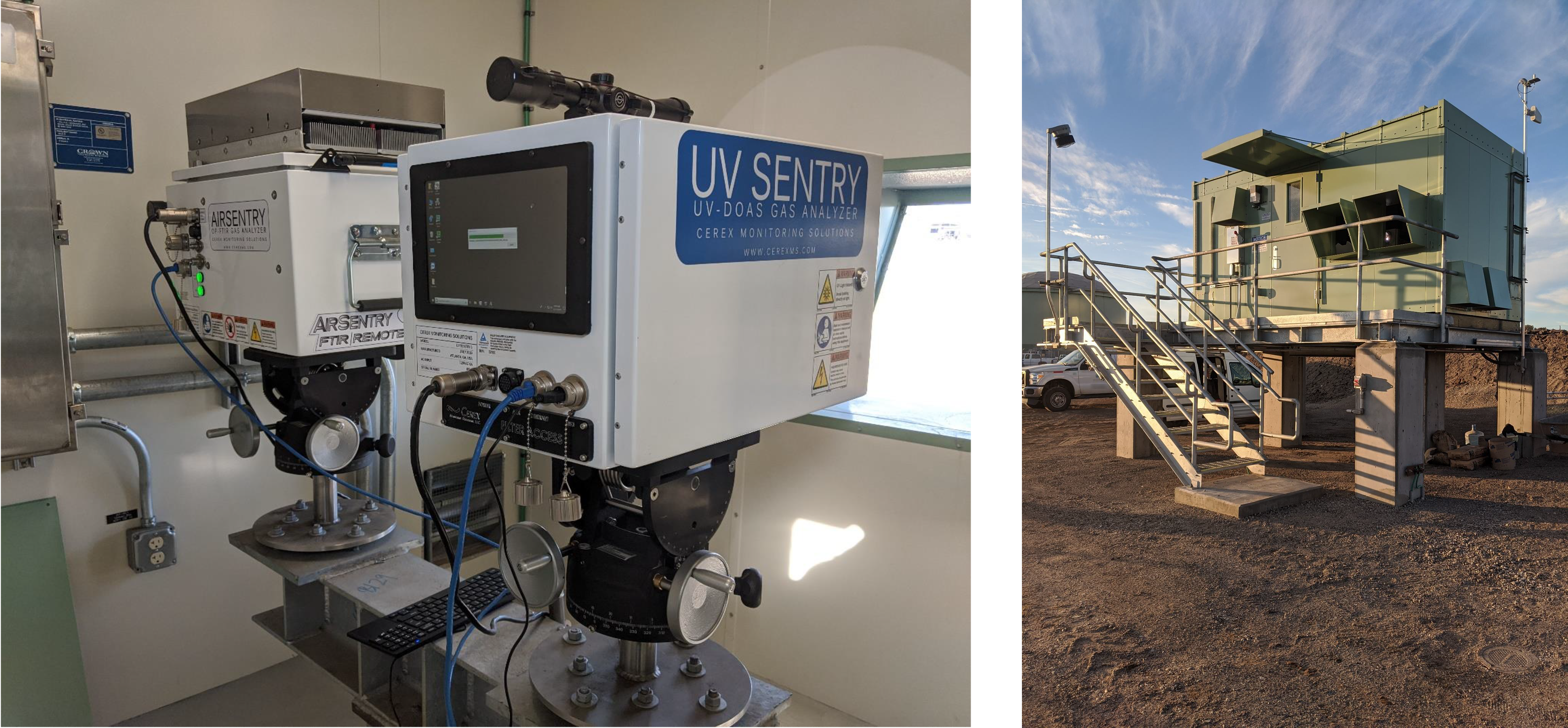

(Left) Concrete columns are used as mounting structure. The floor of the building has holes that allow the concrete column to pass into the building without making contact with the structure. Isolation of the mount column aids in maintain proper alignment. The fixed mount adapter bolts to the column. A pan and tilt alignment mechanism then attaches to the mount adapter. The analyzer attaches to the pan and tilt mechanism using a dovetail mount. The front and rear analyzer hoods are removed to allow more clearance around the installation. The diameter of the hole for the beam is 5.5”.

(Top Right) Shelter for one of the UV Sentrys, measuring BTEX and SO2. The building is air conditioned. Small holes covered by hoods allow the UV Sentry beams to pass through the walls. Large fans are installed to mitigate accumulation of ozone produced by the analyzers. Path lengths are between 320 meters and 590 meters (one way).

(Bottom Right) View of UV Sentry light beam from the retro-reflector end of the path. In the photo, the reflector is mounted overhead to the right side. This is the shortest monitoring path of the six installed units and is 321 meters from analyzer to reflector.

Marathon

Los Angeles – Carson & Wilmington

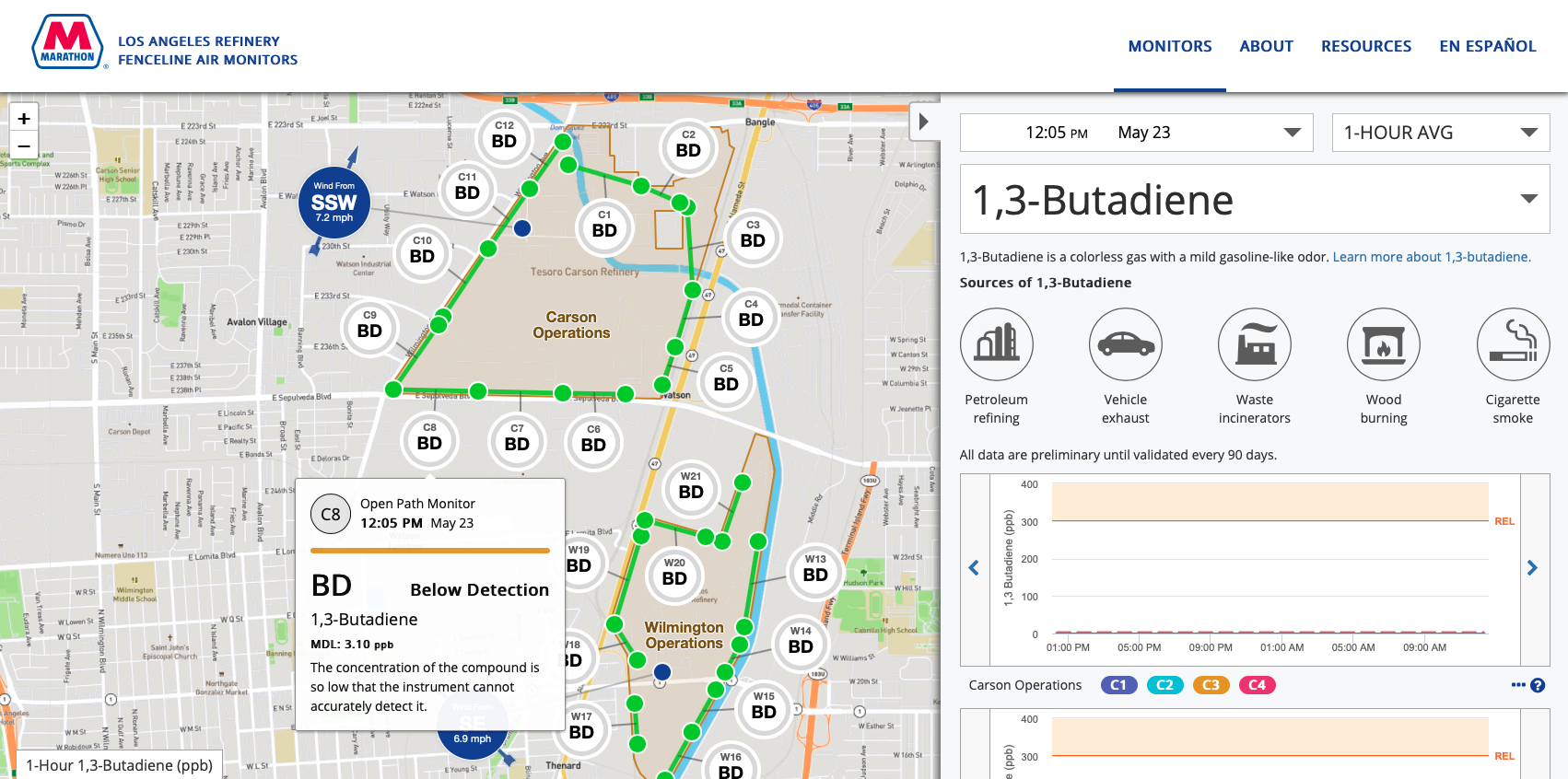

The Los Angeles Refinery is the largest refinery on the West Coast, with a crude oil capacity of 363,000 barrels per calendar day. When South Coast Air Quality Management District (SCAQMD) Rule 1180 went into effect late 2017, Cerex was consulted to provide a solution that would comply with the new stipulations, as well as accurately distinguish the refinery’s emissions from the neighboring emission sources (Alameda corridor rail network, multiple chemical plants, other refinery operations).

Cerex provided 21 UV Sentrys and 21 Air Sentry FTIRs that continue today to monitor pollutant concentrations across hundreds of meters of refinery fenceline. Target gases such as Sulfur Dioxide and BTEX compounds are monitored by the Cerex UV Sentrys, while Nitrogen Oxides, Formaldehyde, Ammonia, and more are monitored with the Air Sentry FTIRs. Results are uploaded to a public-facing website.

Monostatic (as opposed to bistatic) instruments have been selected to reduce the need for substantial power at the mirror sites and improve minimum detection limits by increasing effective path lengths; thus, shelter and other resources are only required at the light-source/detector end.

Products Used in this Solution

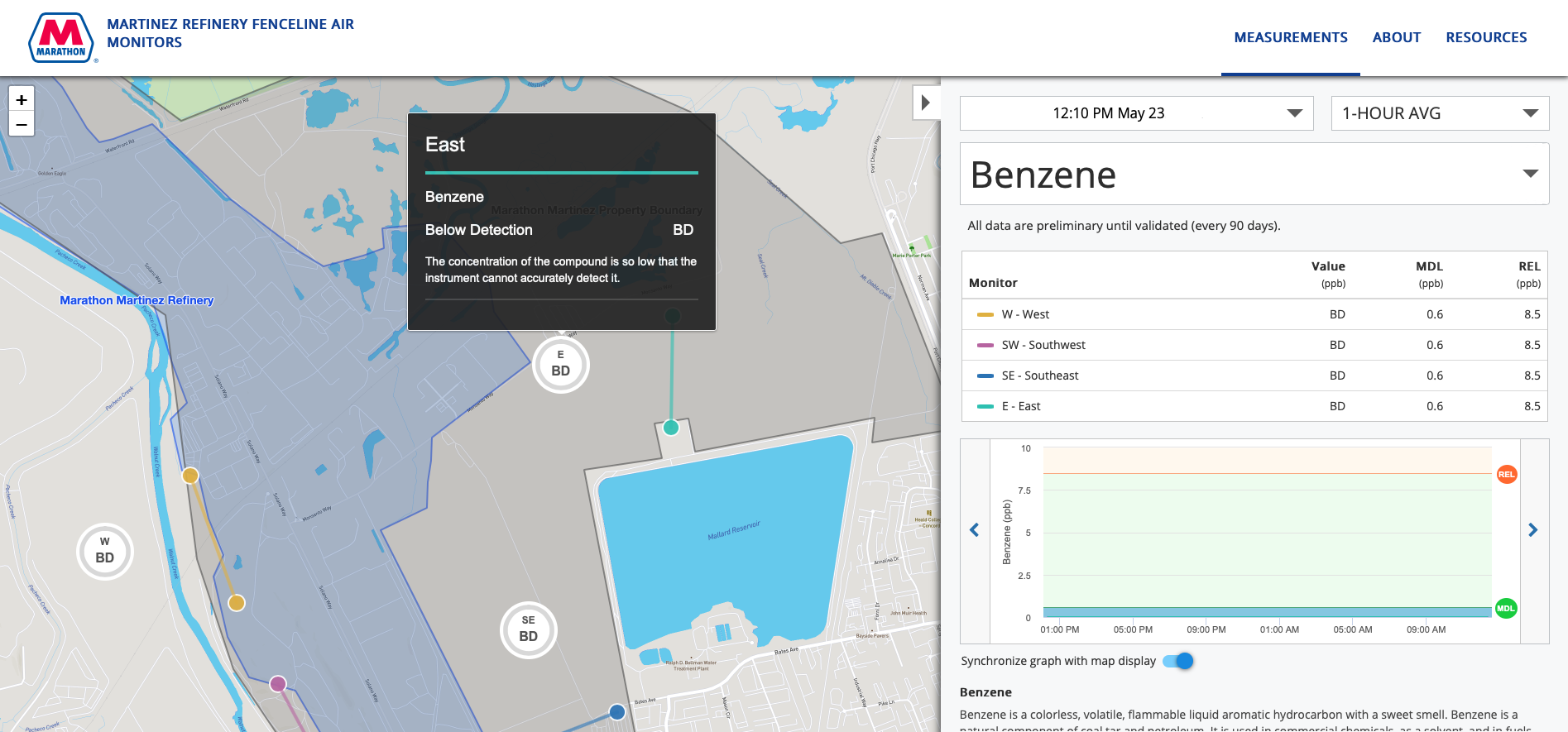

In 2017, Cerex was consulted to help Marathon meet Bay Area Ambient Air Quality Monitoring District (BAAQMD) Rule 12-15. This rule imposes special requirements for fence line monitoring systems and details criteria of fugitive emissions crossing refinery property boundaries into surrounding communities (similarly to SCAQMD Rule 1180).

In accordance, Cerex created a solution for the Martinez refinery that continues to ensure gapless perimeter monitoring. A total of 8 open-path analyzers specifically monitor the gases in question; 4 Cerex UV Sentrys for BTEX and SO2 and 4 Cerex Air Sentry FTIRs for NH3 and 1,3-Butadiene. Additionally, H2S is monitored with monostatic TDLs (provided by Cerex). Results are uploaded to a public facing website.

Products Used in this Solution

Refinery “C”

El Segundo

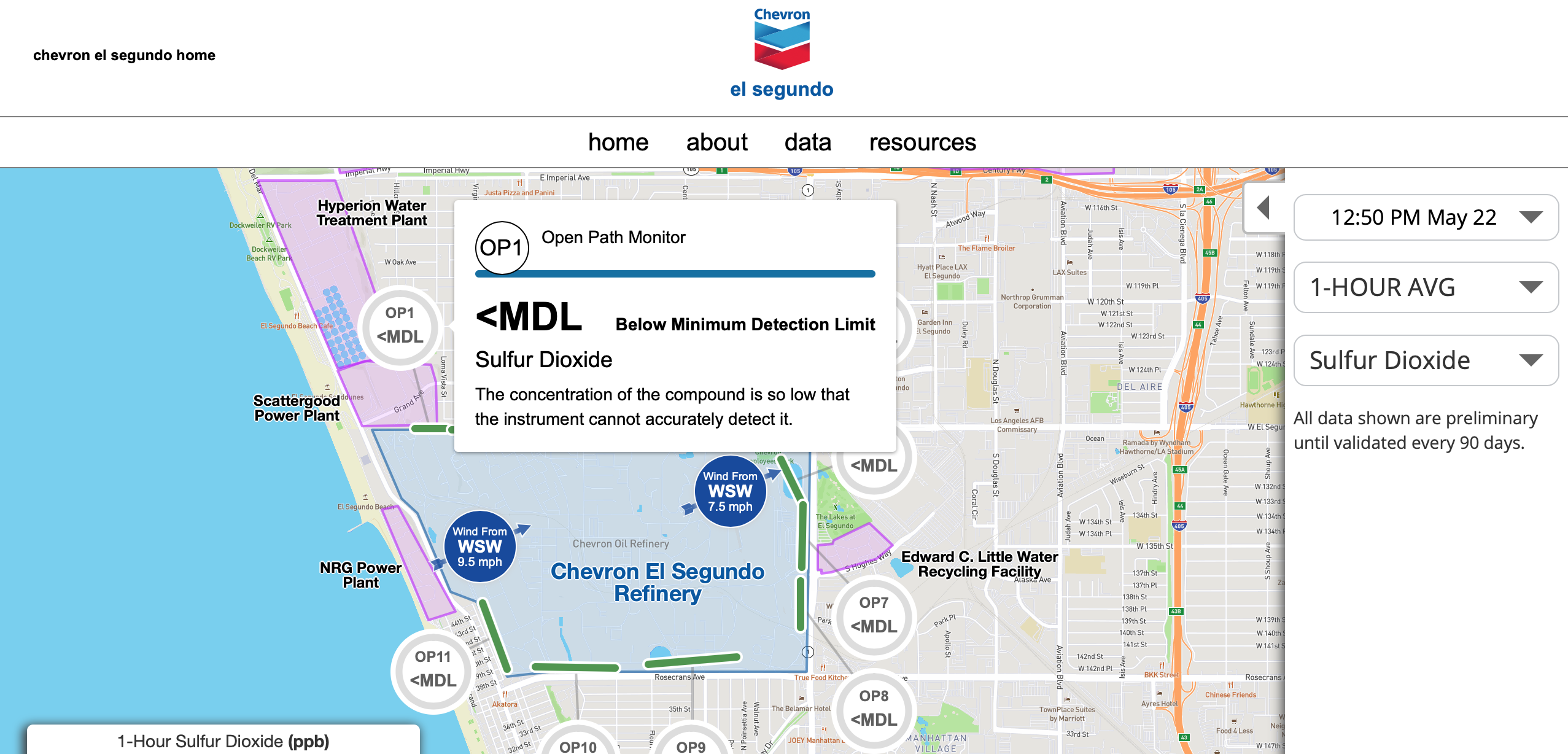

In accordance with SCAQMD Rule 1180, the El Segundo Refinery uses 12 UV Sentry and 12 Air Sentry analyzers to monitor ambient air over roughly 4,000 meters of refinery fenceline. These open path analyzers measure, in real-time; BTEX, SO2, NO2, Acrolein, Formaldehyde, and Naphthalene fugitive emissions.

The Cerex AirSentry FTIR in particular measures fugitive emissions of more than a dozen compounds, including; Acrolein, 1,3 Butadiene, Styrene, Pentane C5, n-Hexane C6, Methane C1, Ethane C2, Butane C4, Propane C3, Formaldehyde, Propene (propylene), Ethene (ethylene), Acetylene, Acetaldehyde, Methanoic Acid, Methanol, Hydrogen Cyanide, Ammonia and Carbonyl Sulfide.

As with other BAAQMD and SCAQMD regulated refineries, all real-time data from Cerex analyzers at the El Segundo refinery is uploaded to a public-facing website – updated every 15 minutes.

Products Used in this Solution

Configuration of El Segundo Air Sentry FTIR and UV Sentry (Left) within protected shelter (Right). Retroreflectors for Air Sentry FTIR and UV Sentry both mounted several feet off the ground to maintain beam path over topography.

Configuration of El Segundo Air Sentry FTIR and UV Sentry (Left) within protected shelter (Right). Retroreflectors for Air Sentry FTIR and UV Sentry both mounted several feet off the ground to maintain beam path over topography.

Cerex provides the Richmond Refinery with 3 open-path UV-DOAS and 3 open-path FTIR systems. Together, these instruments (the UV Sentry and Air Sentry FTIR) continuously monitor 11 compounds, including Alkanes, BTEX, Hydrogen Sulfide, and more, in accordance with BAAQMD Rule 12-15.

The Richmond Refinery was particularly concerned about the FTIR detection of individual alkanes in its warm and humid environment (96°F and 86% humidity). Cerex was contacted about the possibility of an open-path FTIR monitor that could accurately operate in this environment; otherwise, alternative and more costly extractive FTIR systems would have to be chosen. Cerex was pleased to provide the Air Sentry FTIR, which continues to reliably and accurately detect these alkanes at parts per billion detection limits across ambient paths over 500 meters. Results can be seen on Richmond’s public-facing website.

Products Used in this Solution

City of Torrance, California (Completed)

Torrance Refinery

USACE (United States Army Corps of Engineers)

Indiana Harbor

The United States Army Corps of Engineers (USACE), Chicago District is the federal authority responsible for operating and maintaining the Indiana Harbor and Canal Dredging and Disposal Project. The project is an important environmental undertaking designed to help “prevent further pollution of Lake Michigan” and remove backlogged sediment which will restore the efficiency of deep draft commercial navigation.

The USACE required an analyzer that would continuously monitor emissions of one fugitive VOC (naphthalene). Based on capital and operating costs, detection limits, path length, and ability to operate in the expected environment, the Cerex UV Sentry was chosen.

Since installation in 2012, 4 Cerex UV Sentrys continue to ensure gapless perimeter monitoring.

Products Used in this Solution

A multi-analyzer solution

The Hanford Site was first established as part of the Manhattan Project in 1943. It carries enormous responsibilities to ensure the containment of radioactive materials and safety of its workforce, the surrounding communities, and environment.

Since 2016, Hanford Vapors (a division of Hanford), in association with Washington River Protection Solutions, has used Cerex instruments to create a vapor monitoring and detection system.

Open-path UV-DOAS and FTIR analyzers (the UV Sentry and Air Sentry) as well as stack analyzers (UV-FTIR) are used to detect dozens of Chemicals of Potential Concern. These include Aldehydes, Hydrocarbons, Inorganic Compounds, and more. More details about Cerex instruments’ involvement with Hanford is located on their project website.

Products Used in this Solution

Other Projects

Cerex has had the privilege of working in different industries and solving various monitoring challenges over the past 20 years. In addition to the fenceline monitoring projects above, Cerex has manufactured portable point analyzers for emergency personnel and hospitals, as well as process analyzers and stack analyzers for refineries, wastewater treatment plants, and more.

Cerex specializes in creating customized solutions to specifically fit your monitoring needs. Our application engineers would be happy to discuss your project with you.