For regulatory compliant refinery fence-line benzene monitoring, technology choices do not end with Method 325 A/B. As a component within a multi-technology approach to 40 CFR 63.658 compliance or as a stand alone system, the Cerex UV Sentry meets USEPA criteria for OP UVDOAS as an alternative method for regulato- ry compliant refinery fence-line benzene moni- toring.

EPA Criteria for OP UVDOAS

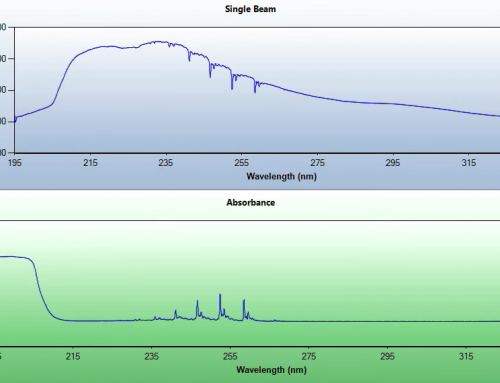

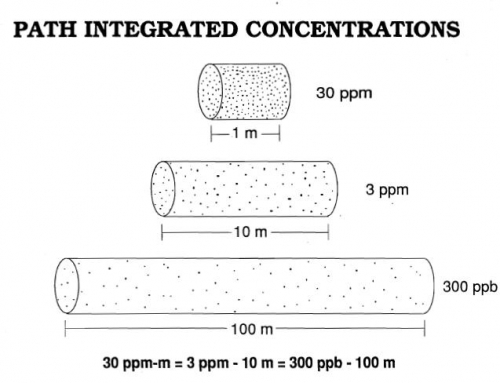

Sub PPB Detection Limits for Benzene

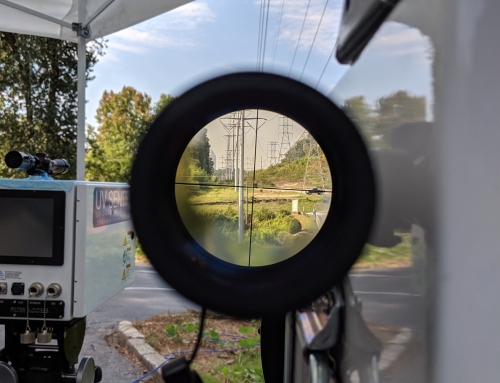

Insitu, Traceable QA Audit at Full Path with Ambient Interferent Gases Present

Time Resolved Monitoring

Real Time MDL Output as DQI

Real Time Signal Intensity Output as DQI Retention of Raw Spectral Data

Importance of EPA Criteria

EPA criteria for UVDOAS has deep roots in TO- 16 and applies to both UVDOAS and FTIR.

EPA tested, the UV Sentry achieves part per trillion detection limits for benzene in real world conditions. Data however is indefensible without traceable QA, and real time data quality may be suspect without real time data quality indicators.

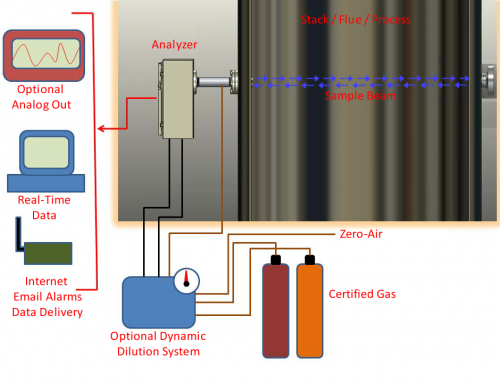

The UV Sentry and AirSentry FTIR both provide real time data validation in the form of signal and minimum detection limit measurements.

Quality assurance audits are multipoint span audits, performed with primary standard calibration gases at installed path lengths with ozone and oxygen present.

Cerex provides three methods for QA, one of which does not require calibration gas to be stored on site:

- External linear QA cell filled offsite with calibration gas. Slides onto analyzer.

- Internal short path linear QA cell for multipoint span audit. Permanently mounted in beam path.

- External half meter linear cell for multipoint span audit. Placed between analyzer and retro-reflector

Like TO-16, using UVDOAS for compliance monitoring requires the analyzer to save raw spectral data.

This data contains a permanent record of the species and concentrations of gases in the air at the time of monitoring.

It is independent of calibration and may be used at any time to verify real time measurements